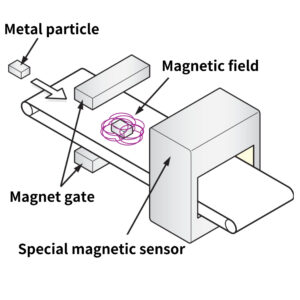

Magnetized Metal Detector

Magnetized Metal Detector

Magnetized Metal Detector NT-series is ultra-sensitive detectors, which have been difficult with conventional metal detectors and feature special magnetic sensors to detect minute magnetic metal contaminants and, in particular, minute SUS wires (Fe φ 0.4mm, SUS φ 0.2 x 2 mm) .

Because the sensor catches only weak magnetic fields generated by magnetic metals, it is not affected by the form of packaging (including aluminum foil wrapping material and aluminum tray) and properties (temperature, salinity, moisture content, etc.) of the object to be inspected.

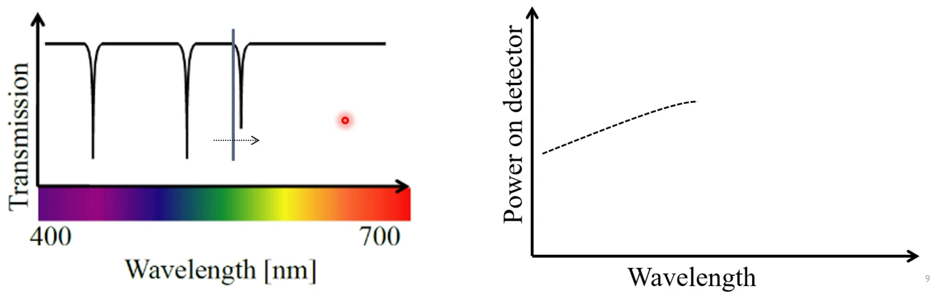

Oxygen Gas Sensor Analyzer

The O2 sensor device transmits light over a range of wavelengths near the optical absorption peak of each molecule (approximately 600 nm for O2) and can then correlate the light transmission data to absorption and concentration.

Magnetized Metal Detector Features

Ultrasensitive detection

Since NT series only catches magnetic fields generated by magnetic metals, there is no influence of the subject to be inspected, and the sensitivity shown in the catalog remains the same as the practical sensitivity.

More Effective

Compared with conventional metal detectors and X-ray foreign matter inspection equipment, this detector can detect SUS wire φ 0.2 × 2mm with less head of detection accuracy due to the approach direction of wire-like metal.

Smallest Running Cost

There is no consumable parts like X-ray Inspector, so the running cost is as energy-saving as the conventional metal detector.

Easy Operation

Easy to use anywhere without complicated initial settings or the need for sensitivity switching for each product. They can be used with the same settings, even if they differ in nature or state.

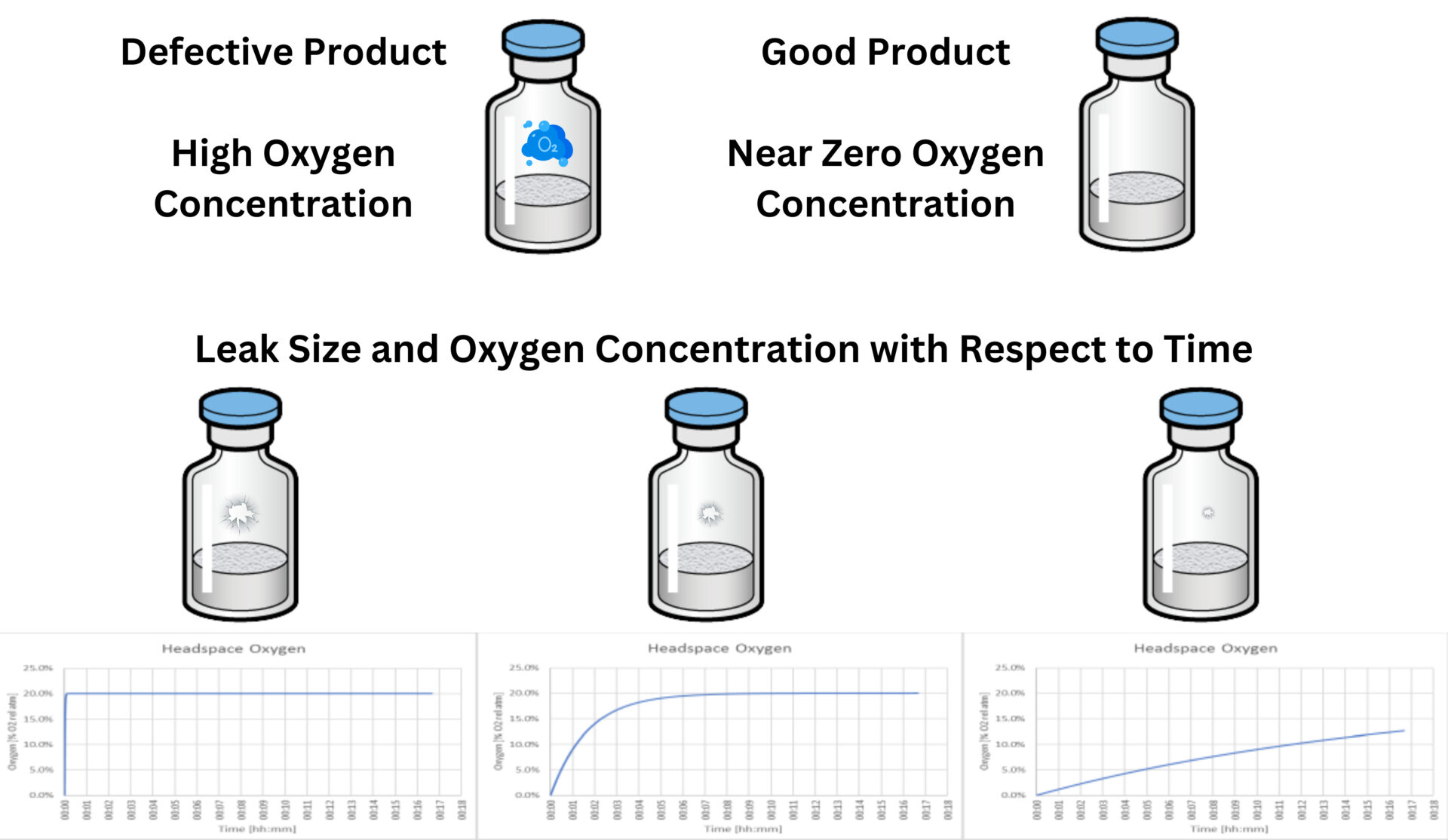

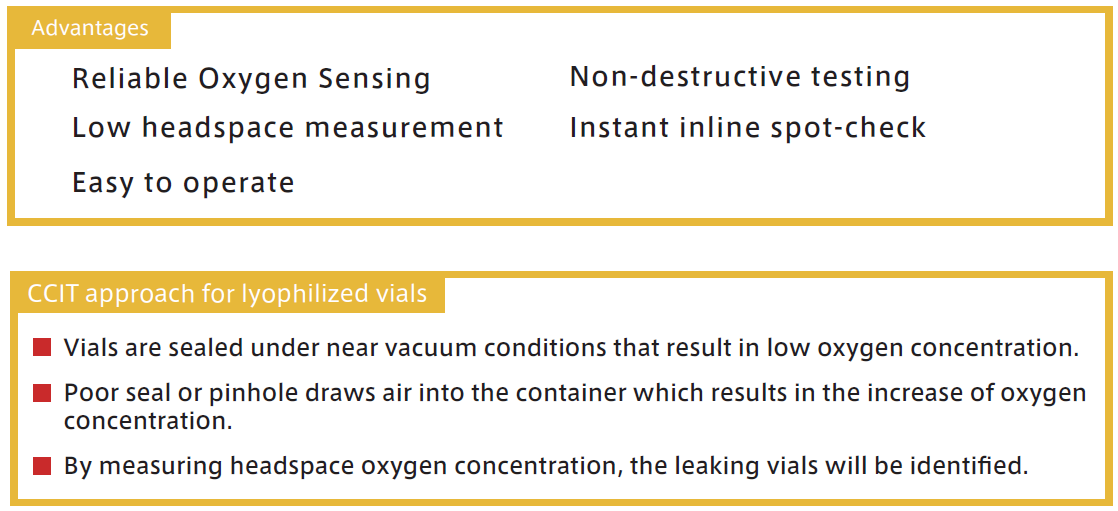

Head Space Gas Analysis

- Headspace gas analyzer for non-intrusive measurements in vials.

- Non-destructive during production, storage or laboratory quality testing.

- GASPOROX sensors allow fast and reliable inspection of parenteral pharmaceuticals in vials.

- Test results will be presented instantly.

- An infrared light passes through the gas headspace of the container and precisely measures the concentration of oxygen.

- The laser light is completely eye-safe.

- The method is non-destructive, deterministic and recommended by USP1207.

Software and HMI

Nikka Densok’s user-friendly data management software and human-machine interface (HMI) guarantee regulation compliance. Our software and HMI system make it easy to manage production data, inspection result data and signal trends with excellent display visibility.

Based on 21CFR part 11, various group management access levels can be defined based on user requirements to determines various access levels. In addition, our system offers data transfer and backup using local folders and LDAP connection. Furthermore, event, alarm, etc. data can be easily managed and analyze, and made hardcopy using the connected printer device.

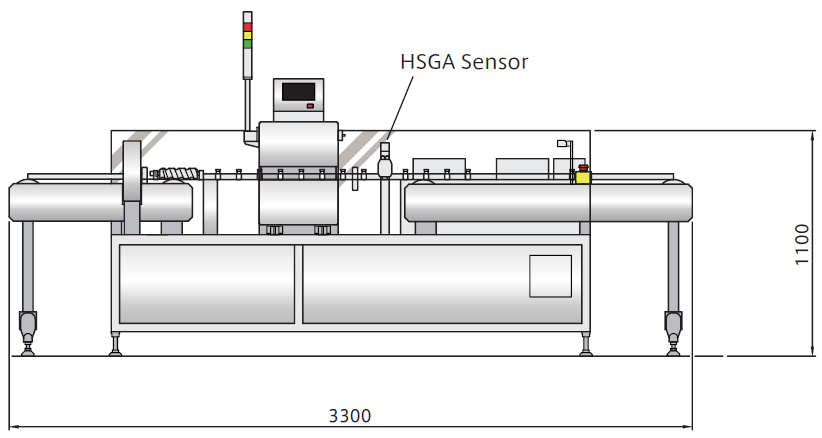

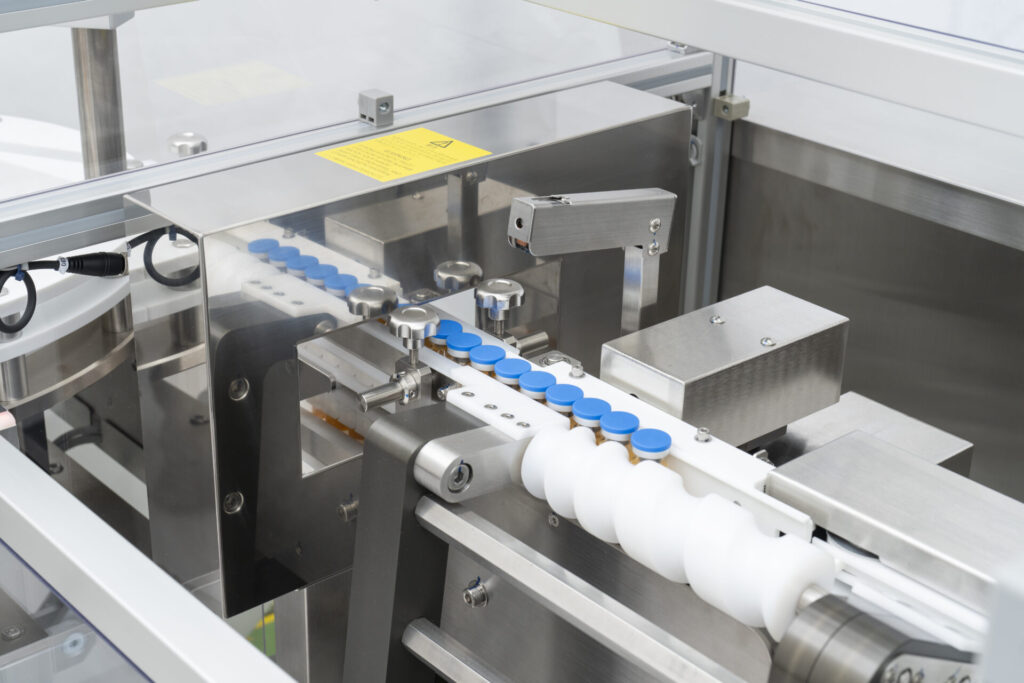

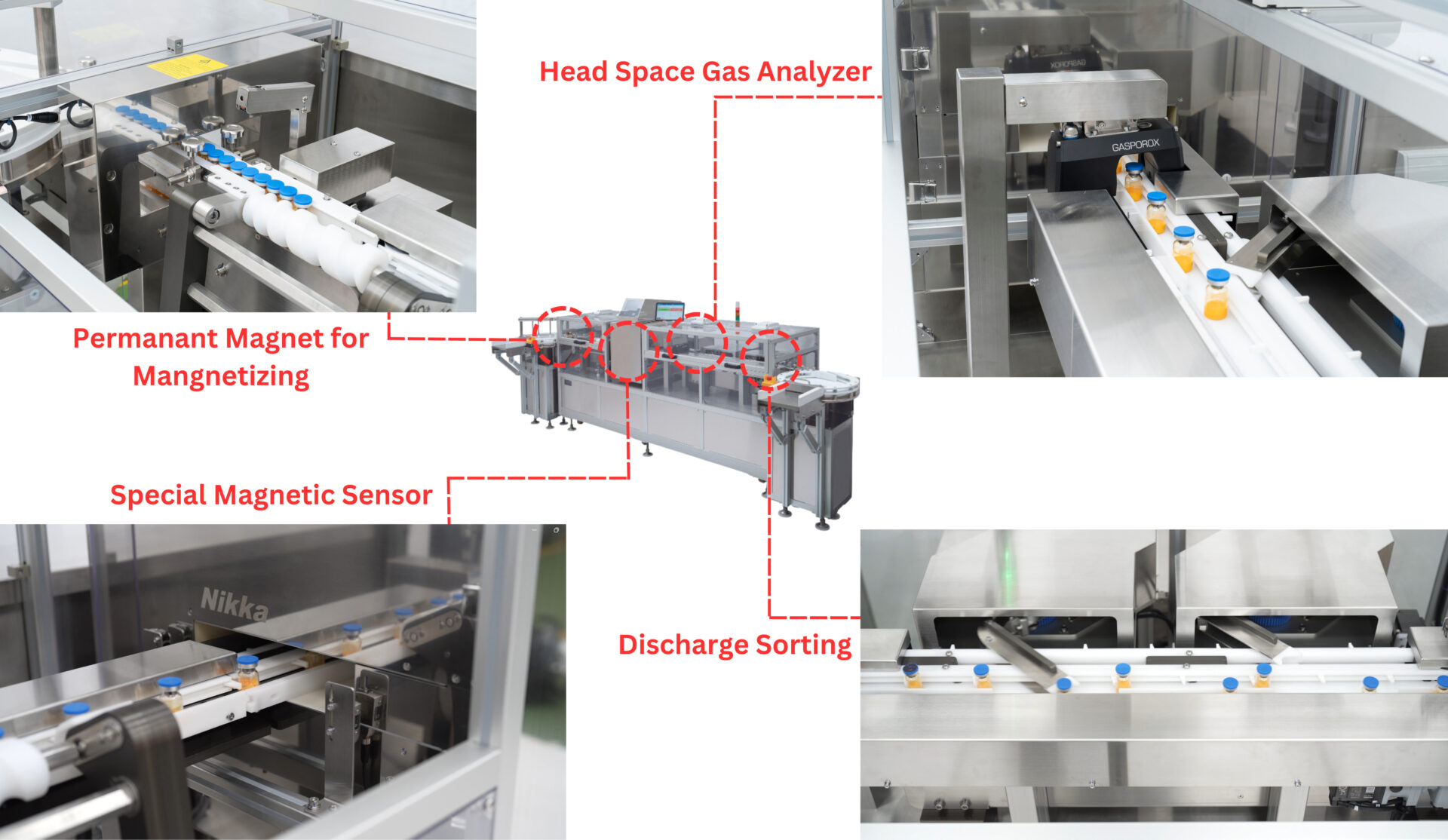

Inline Lyo Vial CCIT and Metal Detector

Lyophilized Vial CCIT and Micro Metal Detector Combination Machine:

This machine reliably detects micro leaks and metal parts in freeze-dried vials by combining an oxygen gas laser sensor and a magnetized metal detection sensor. In addition, this machine is equipped with an innovative sorting system that can safely separate good and defective vials at high speed. This machine can also be easily connected to upstream and downstream equipment in the production line.

NT-HSGA Series Specifications

The following table shows the processing specifications and layout of the NT-HSGA series. The infeed and discharge sections can be customized to match the customer’s production line.

| Model | NT-HSGA |

|---|---|

| Processing Capacity | Up to 300pcs/min |

| Vial Size | Up to 30mL |

| Power Consumption | 5.0kVA |

| Power Supply | 200 - 480VAC. 50/60Hz |